Recently a client called me to investigate noise in his commercial unit located next to a dentist’s office. I have had a similar case previously, but this one was different. The noise sounded like an organ pipe whistle.

More...

Noise Investigation

After further noise investigation, the source of the disturbance was determined to be mechanical equipment located in a small room within the dental clinic, positioned adjacent to the partition separating the client’s unit from the clinic. The equipment was installed in the under-sink cabinet space and included the following:

The partition wall in question is constructed with 3.5-inch steel studs and one layer of drywall on each side. The wall contains an enlarged internal cavity, approximately 8 inches deep, which appears to house drainage and water supply piping. The cavity is filled with mineral wool insulation. The presence of insulation was confirmed by inserting a feeler rod through the electrical outlet opening on the wall.

Sound Pressure Level Test

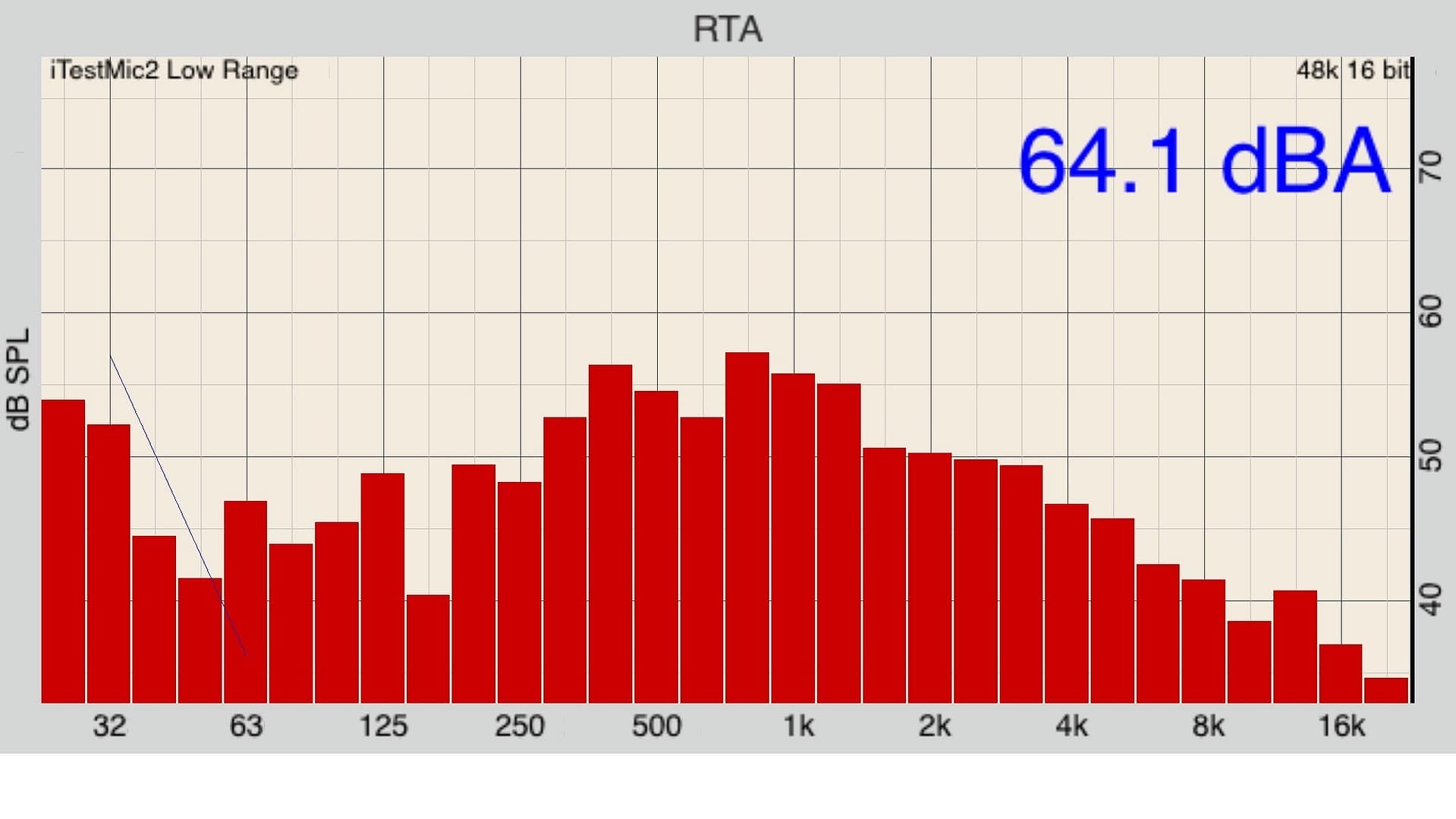

As part of the noise investigation, I have measured the noise levels in the small room containing the equipment in the dental clinic. The test result is shown in Image 1 below.

Image 1 - Noise level spectrum at vacuum pump location

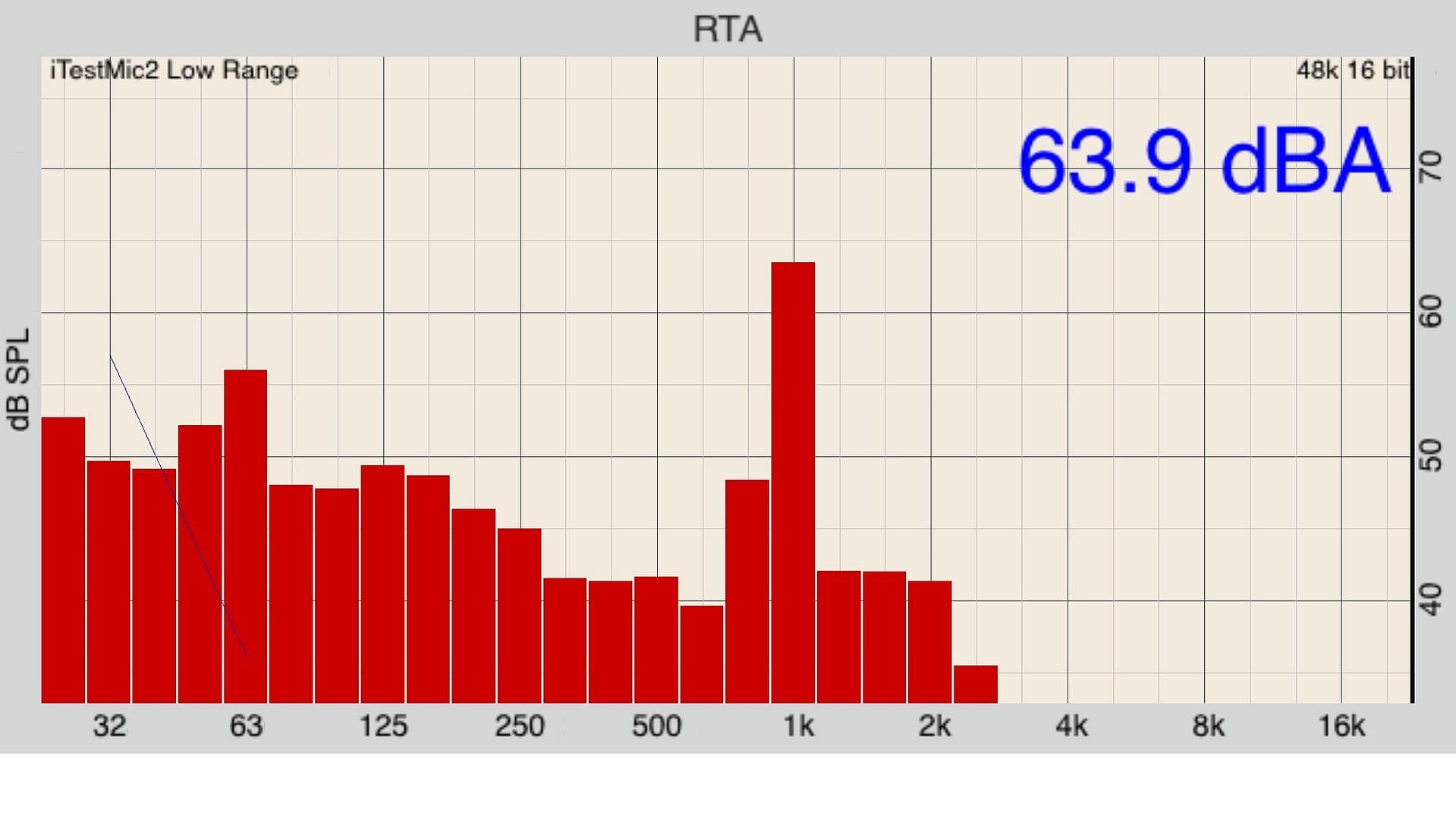

I have then tested noise level in client’s unit, in front of washroom that is adjacent to the location of the noise source, with washroom doors open. The result is shown in Image 2 below.

Image 2 - Noise level spectrum in the adjacent unit

Analysis of Test Results

Noise investigation showed that the noise of the mechanical equipment (Image 1) is normal. The recorded 1/3 octave band spectrum is as expected from this type of equipment.

Image 2, recorded in the hallway of the adjacent unit with the washroom door open, shows a strong harmonic signal (whistling) at approximately 1 kHz. The noise level in this location is nearly as high, in decibels, as the noise measured at the source behind the drywall partition. This is highly unusual, as one would normally expect the partition to provide measurable sound attenuation. Additionally, the spectral characteristics of this noise (Image 2) do not correspond to the source spectrum shown in Image 1.

The most reasonable explanation is that the partition between the two units is exhibiting an internal resonance. In this scenario, sound energy from the mechanical equipment excites the air volume in the drain pipe, causing it to function as an acoustic resonator that re-radiates sound into the adjacent unit with minimal loss.

Troubleshooting the Source of Noise

Furthermore, the dentist indicated that when the toilet in their patient’s washroom (not adjacent to the room with the vacuum pump) was removed for repairs, one could hear the same high-pitched noise emitted by the open drainage stack. This indicates that the noise is transmitted through the building’s sanitary drain system.

I then inspected the manufacturer’s installation instructions for the vacuum pump and found that the equipment was not installed correctly. The exhaust separator was not installed. This omission was confirmed by the manufacturer of the pump as the cause of the noise.

The noise investigation concluded that the harmonic noise heard in my client’s unit was caused by the incorrect installation of a vacuum pump in the adjacent dental office. The exhaust from the pump was connected directly to the building’s plumbing (Photo above). The pump generated harmonic resonant noise within the sanitary plumbing pipes. It sounded like a musical organ pipe. The plumbing pipes are located inside the wall separating the units in question, and the noise was transmitted through the drywall into the adjacent unit.

Fixing the Noise Problem

As recommended by the vacuum pump manufacturer, proper installation requires an exhaust separator between the pump and the drain. The pump’s supplier and installer should add this item to the vacuum pump’s installation. The installation instructions for the vacuum pump require the use of the exhaust separator.

If you have comments about this article, please fill in and submit the form below.